As the movement to realize a decarbonized society is accelerating globally, the aviation industry is also taking steps to reduce CO2 emissions. One such initiative is the introduction of sustainable aviation fuel (SAF). The IHI Group is currently developing a Power-to-Liquid (PtL) technology to produce liquid hydrocarbons for SAF from hydrogen and CO2 with renewable energy. We interviewed Shinya Okuno and Jian Huang of the Sustainable Aviation Fuel Business Planning Group, Technology Planning Department, Corporate Research & Development Division.

Okuno said that he had been interested in the global environment since he was a student. “The effect of CO2 attracted attention in the late 1990s due to the Kyoto Protocol and other matters. Back in my elementary school days, environmental issues such as the ozone layer depletion were being discussed worldwide, which drew my interest when I was watching them on TV. I was like a bandwagon fan, though,” he said with a laugh.

“I majored in that field in university, and in the laboratory, I was thinking about how to create environmentally friendly energy sources, such as fuel cells, that do not use fossil fuels. Since joining IHI, I have been working in the environment- and energy-related field, starting with the development of CO2 capture and other technologies.”

Huang studied technology related to coal-fired power generation at a university in China. Looking back, he said, “It was 20 or 30 years ago, when demand for coal was still expected to grow in China. On the other hand, the environmental impact of SOx (sulfur oxides) and NOx (nitrogen oxides) emissions was starting to be recognized as an inevitable problem.”

He decided to start his doctoral course in Japan, which had highly advanced technology for improving energy efficiency and reducing CO2 emissions. Since joining IHI, he had been involved in the development of the carbon dioxide capture and storage (CCS) technology. In the Sustainable Aviation Fuel Business Planning Group, he is supporting the development of SAF from a marketing perspective as well.

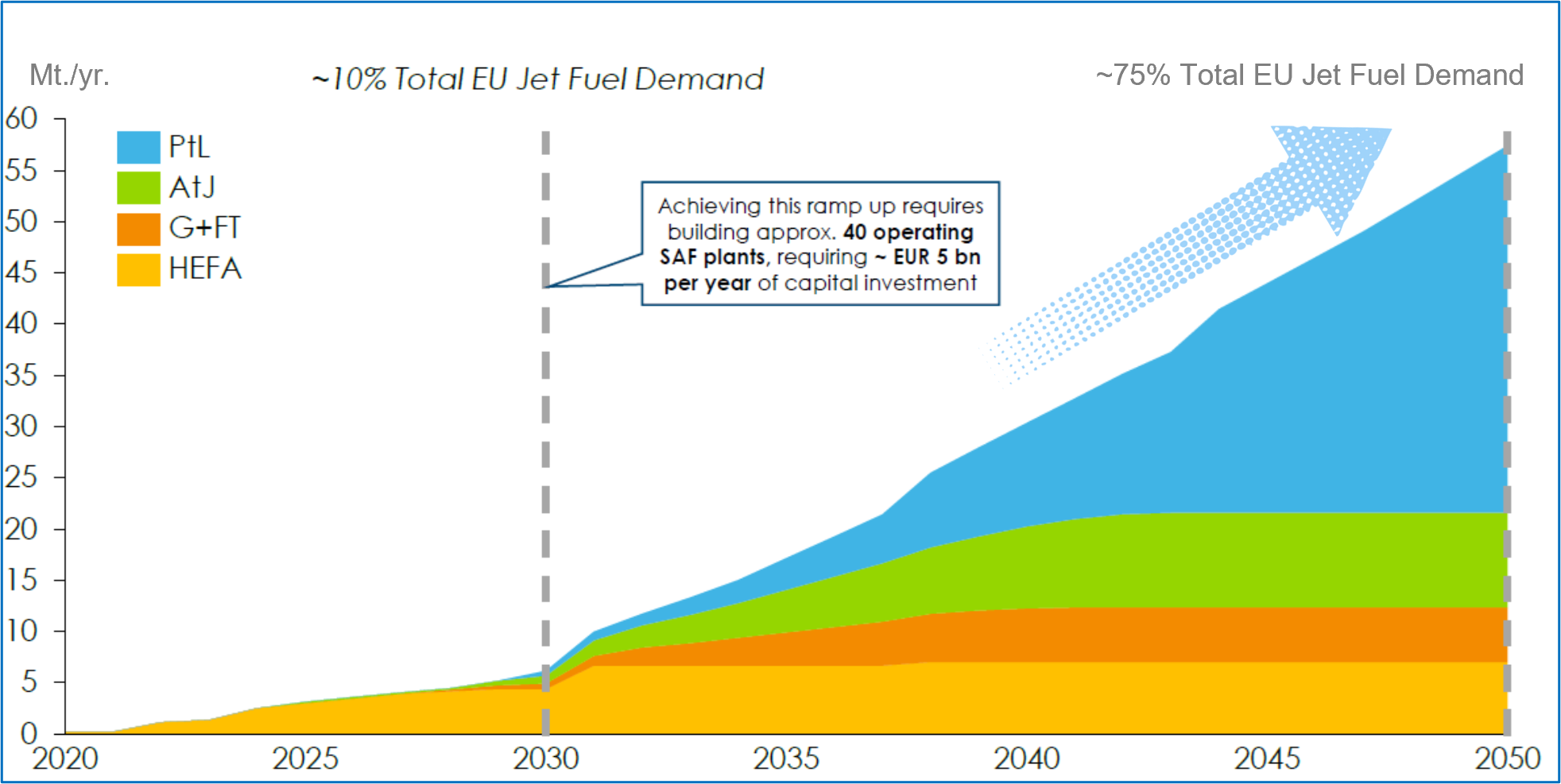

Okuno explained the reason why IHI is developing the PtL, “The technology to make SAF from waste cooking oil and other biomass is already progressing and has already been commercialized. However, it is expected that there will not be enough biomass resources due to increased demand of SAF in the future.” He also says, “In contrast, CO2 is available everywhere in the world and is enormously abundant. The use of PtL, which uses raw materials with no quantitative constraints for future demand, is expected to grow after around 2040.”

Since 2011, the IHI Group has been developing methanation technology to produce synthetic methane (e-methane) from hydrogen and CO2 jointly with A*STAR ISCE2 (Institute of Sustainability for Chemicals, Energy and Environment). “We have developed the catalyst technology for carbon dioxide capture and effective utilization (CCU), and in the meantime, the aviation industry has the issue of decarbonization. Furthermore, IHI is involved in jet engines as a business, so we needed to start working on SAF so that jet engines will contribute to a future sustainable, decarbonized society,” said Okuno.

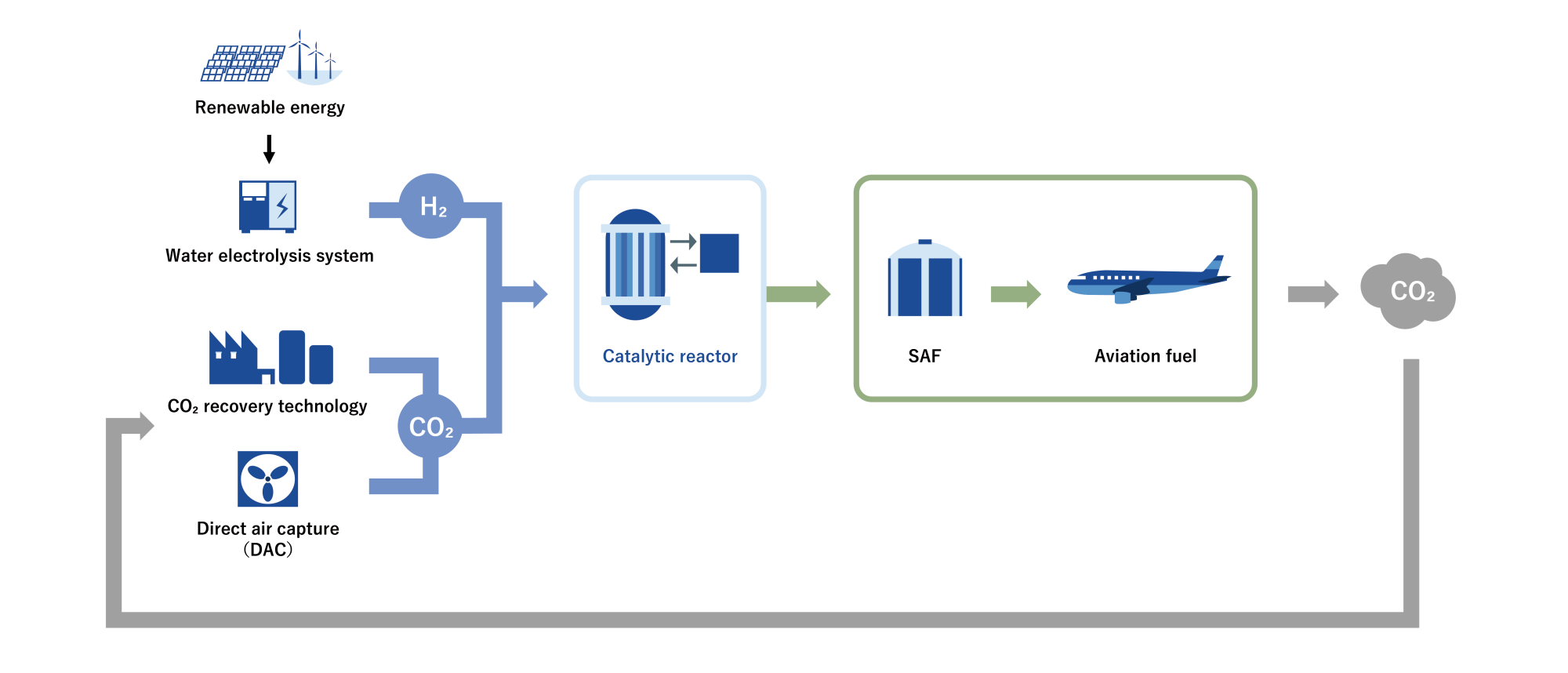

In the PtL process, hydrocarbons are generally produced by converting CO2 to CO (carbon monoxide), what is called Reverse Water Gas Shift reaction, and then chemically reacting hydrogen and CO, what is called FT(Fischer-Tropsch) reaction. The IHI Group is researching direct-FT, which combines these two processes into one. By simplifying the PtL process, the company can expect to improve energy efficiency and reduce equipment costs.

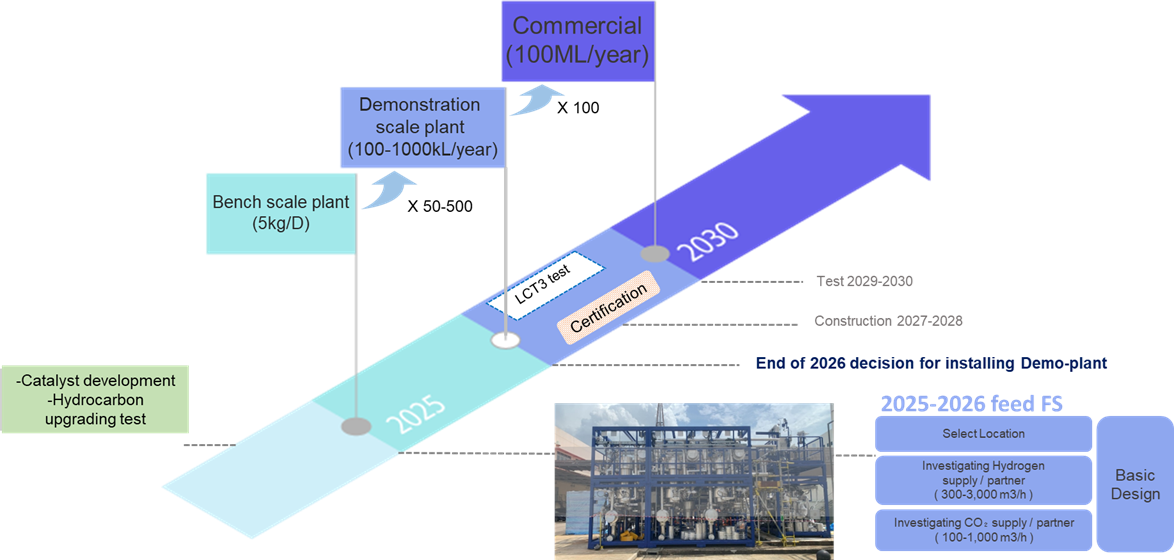

IHI developed a new catalyst to synthesize SAF from CO2 in collaboration with ISCE2 and confirmed a world-class 26% liquid hydrocarbon yield in a catalytic reaction test in December 2022. On the other hand, “There is still room for improvement in the robustness of the catalyst to maintain stable performance over a long period of time, which we are focusing on in the next development phase,” said Okuno. In January 2025, the verification of a series of processes started in Singapore with a newly installed test rig.

To turn the hydrocarbons into standard-compliant jet fuel, a process of upgrading hydrocarbons is required, and “this is an area where commercialization is already underway, so we are trying to acquire the process by partnering with companies that have the technology,” said Okuno. He explained, “We want to carry out development in-house in the area where IHI’s strengths can be utilized, and then accelerate the entire process to produce SAF by successfully combining the technologies of other companies with ours.”

In relation to collaboration with other companies, Huang said, “Let me talk about one of our hardships. Looking at the entire SAF value chain, a major challenge we face is obtaining inexpensive hydrogen and CO2. Simply synthesizing an expensive SAF from costly hydrogen and CO2 will not be accepted by the aviation industry. It is also important to reduce overall costs by improving catalyst performance, and the researchers are working hard on R&D to achieve this.”

It is also essential to reduce CO2 emissions over the entire life cycle, based on the Carbon Offsetting and Reduction Scheme for International Aviation (CORSIA) established by the International Civil Aviation Organization (ICAO) and other schemes. “We need to think about how much CO2 emissions can be reduced throughout the entire value chain from hydrogen and CO2 procurement and SAF manufacturing to transportation and feeding into the aircraft. This cannot be done by a single company, because it requires data from all parties involved, from upstream to downstream, to make calculations,” said Huang.

There is another barrier to commercialization. SAF, which has almost the same composition as conventional jet fuel, can be used without significantly changing the existing infrastructure. However, this requires compliance with the standards for jet fuel established by ASTM International. There are currently eight SAF manufacturing processes approved by ASTM, most of which are based on biomass-derived raw materials such as waste cooking oil, and there are no CO2-derived processes that have been approved.

When using a process that has already been approved, it is possible to just manufacture the fuel accordingly. Pioneers must overcome barriers themselves. However, the IHI Group has experience in obtaining SAF approval using algae (microalgae) as the seventh of the eight processes. Okuno said with confidence, “It is difficult to obtain certification in a short period of time without the necessary knowledge, but the people who were in charge of the project then are also in the current team. We are able to utilize our past knowledge, and do not think it is a very high hurdle.”

They will continue to verify the process with the test rig while solving such issues, with the goal of starting installation of a demonstration plant in FY2026. “We are confident that we will be able to produce SAF at a competitive cost if we complete the current technological development, after setting benchmarks with other companies. Our mission is to firmly establish the technology and bring it to commercialization,” he stressed.

Since the demonstration plant requires expenses and land of a scale much different from the test rig, Okuno said, “We are working on publicity activities to look for partners who can work with us on the next demonstration and semi-commercial activities.” He added, “As a company with a jet engine business, we would like to promote to the aviation industry that we will continue to provide not only engines that emit CO2 but also other products that contribute to CO2 emission reduction.”

“The ‘S’ in SAF stands for ‘sustainable,’ so our business also needs to be sustainable. Through this development, we hope to transform our company into a sustainable business entity as well as to enhance the sustainability of our products,” he stated with determination.

Huang chuckled, “There is nothing more to say,” but added, “We have 25 more years to achieve carbon neutrality by 2050. It may seem long, but it is short, and it cannot be achieved by the IHI Group alone. We will run out of time unless we work together with people in various companies and countries, so let us work together to develop technologies and create a better future together.”

The two young men came from different countries but embarked on a path of research with the same goal of tackling common environmental issues that transcend national borders. Today, their aspirations have not changed, and they are taking on the challenge of realizing sustainable aviation fuel together with like-minded partners around the world.

With assistance from:

Shinya Okuno|Sustainable Aviation Fuel Business Planning Group, Technology Planning Department, Corporate Research & Development Division

Jian Huang|Sustainable Aviation Fuel Business Planning Group, Technology Planning Department, Corporate Research & Development Division